| Availability: | |

|---|---|

| Quantity: | |

Advantages of RollMac's PU Foam Sandwich Panel Machine

1. Fire prevention reaches B2 level

2. Insulation performance reaches refrigerator or cold storage level

3. Compared to low pressure, high-pressure makes AB material more homogeneous, better quality of foaming, and longer service life

4. High yield, saving more than 7-9% raw materials compared with low-pressure foam

5. Foaming system has a self-cleaning function, the spray head does not need to be cleaned, easy to use and maintain

6. Original flying saw cutting system, greatly reducing labor costs

7. Unique pressure detection protection device ensures the operation of the machine is safer and more stable

8. Have options: * PU sheets with metal sheet and PVC paper (thickness: 20mm, 50mm)

* Both sides metal sheets (thickness: 20mm, 50mm)9. Widely used in various construction industries such as cold storage,refrigerators, hospitals, cars, stadiums, villas, high-end buildings, etc. The performances of our PU line reach to the advanced level of similar products at home and aboard.

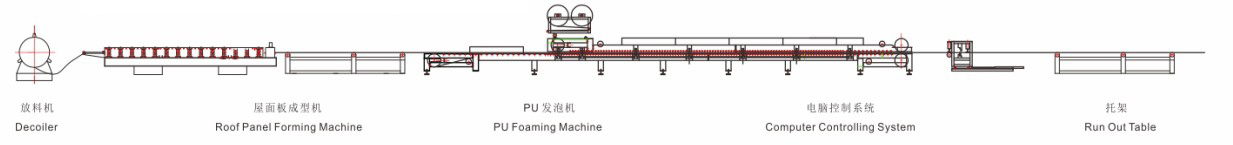

Flow Chart of PU Foaming Line:

Profiles Of Roll Forming Machines:

No. | Machine Components | Unit | Quantity |

1 | 5 Tons Hydraulic Decoiler with car | Set | 2 |

2 | Roll Forming Machine | Set | 2 |

3 | High Pressure PU Foaming Machine | Set | 1 |

4 | PLC Controlling System | Set | 1 |

5 | Servo Motor Cutter | Set | 1 |

6 | User Manual 1 Copy | - | - |

5 Tons Hydraulic Decoiler with Loading Car |  | |

Specification | Value | |

Size | 3900*1250*1600mm | |

Weight | 2500kg | |

Motor Power | 3kw | |

Hydraulic Engine | 2.2kw | |

Voltage | 415v/50hz/3ph | |

Outer Diameter | 1250mm | |

Max. Support | 5 tons | |

Inner Diameter | 508mm | |

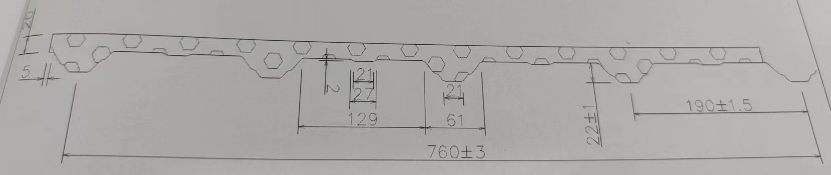

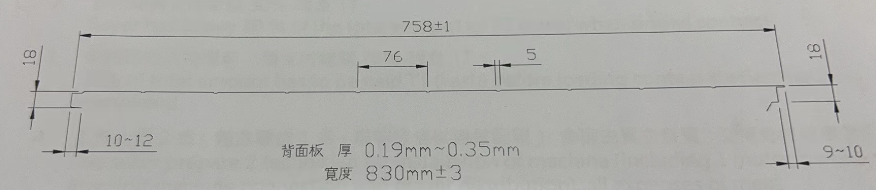

Specification | YX22-760 Roof Sheet Forming Machine | YX20-758 Baseplate Forming Machine |

Size | 7500*1400*1200mm | 8000*1500*1200mm |

Weight | 5500kg | 5500kg |

Capacity | 5.5kw | 5.5kw |

Hydraulic Engine | 2.2kw | 2.2kw |

Voltage | 415v/50hz/3ph | 415v/50hz/3ph |

Rolling Speed | 15m/min | 15m/min |

Roll Stations | 18 Stations | 16 Stations |

Thickness | 0.3-0.6mm | 0.2-0.35mm |

Test Material Thickness | 0.4mm | 0.3mm |

Height Tolerance | ±1mm | ±1mm |

Width Tolerance | ±5mm | ±5mm |

Effective Width | 760mm | 758mm |

Feeding Width | 914mm | - |

Material Strength | PPGI G500 | PPGI G500 |

Accessories | Main Machine | Main Machine |

Hydraulic System | Hydraulic System | |

PLC Computer Controlling System | Hydraulic Pre-cutter | |

Forming Cutter | PLC Computer Controlling System | |

Manual in English | Manual in English |

High Pressure PU Foaming Machine 1 Set:

1.High Pressure PU Foaming System:

(1) The black and white raw materials are mixed under high pressure to make them fully foamed,which saves 7-9% of raw materials compared to the low-pressure foaming system.

(2) The nozzle has a self-cleaning system, which does not need to be removed for cleaning after each use.

2. Spout Head with Self-clearing System

3. Heating system

4. Rubber Belt

PLC Controlling System PLC 1 Set

|  |  |

Roll Forming Machines Control System | PU Foaming Machine Control System | Sevo Motor Cutter Control System |

Sevo Motor Cutter 1 Set

Sample & Project

content is empty!