| Availability: | |

|---|---|

| Quantity: | |

This series of rolling door machines is mainly used to produce different types of rolling shutter door panels. The machine can not only form the panels but also punch holes and emboss patterns. In addition, the panel profiles can be customized to meet specific requirements.

0.6-1MM

Thickness Range

27m/min

Production Speed

14 Stations

Roll Forming Step

Model | JM-85 |

Machine Dimension(L*W*H) | 4000*900*1400mm |

Weight | 2500KGS |

Motor Power | 4KW |

Hydraulic Power | 2.2KW |

Voltage | 380V/50HZ/3PH |

Forming Steps | 14 steps |

Production Speed | 20m/min |

Material Sheet Thickness | 0.6-1.0mm |

Feeding Material Width | 136mm |

Profile Effective Width | 85mm |

Tolerance for length cutting | ±2mm |

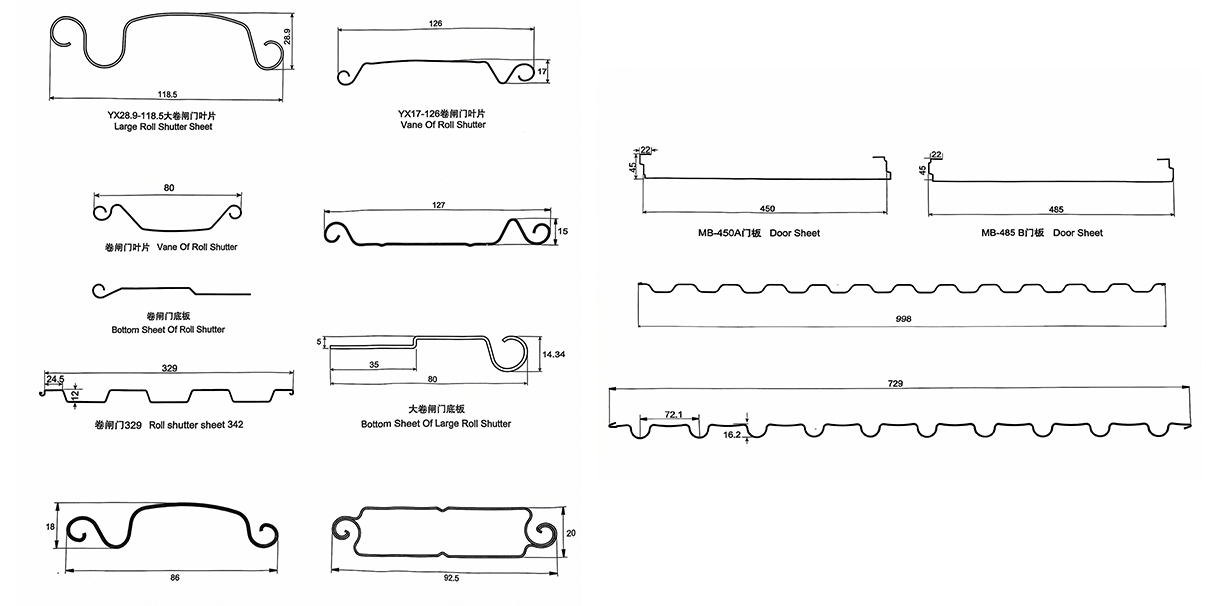

Profile drawing (can be customized)

Key Features and Capabilities of Roll-Up Door Roll Forming Machine

· Adjustable Rollers: Designed to fit different door profiles and sizes.

· Computerized Control: Ensures accurate shaping and cutting with high precision.

· Built-in Safety: Equipped with safety features to protect operators during operation.

· High Production Speed: Capable of meeting large-scale production demands.

· Wide Material Range: Handles various material thicknesses and widths for different door specifications.

These machines are widely used by roll-up door manufacturers to produce large volumes of panels efficiently and with consistent quality. They are essential in the industrial door manufacturing process, ensuring doors that are reliable, durable, and suitable for diverse applications.

content is empty!