RollMac-310

| Availability: | |

|---|---|

| Quantity: | |

Light-gauge steel framing systems are built using cold-formed steel sections and can be applied throughout an entire structure. With the help of advanced equipment such as a metal framing machine or cold formed steel framing machine, the system automatically generates fabrication drawings, structural layouts, cut lists, and material reports. By automating these tasks, manufacturers save significant time on drafting, data entry, material planning, production, and error correction. For those seeking efficient solutions, a light steel framing machine for sale offers a practical way to streamline steel construction projects

1.5-2.5MM

Thickness Range

35m/min

Production Speed

8m × 1.2m × 1.2m

Dimensions L x W x H

See the RollMac C310 in Action

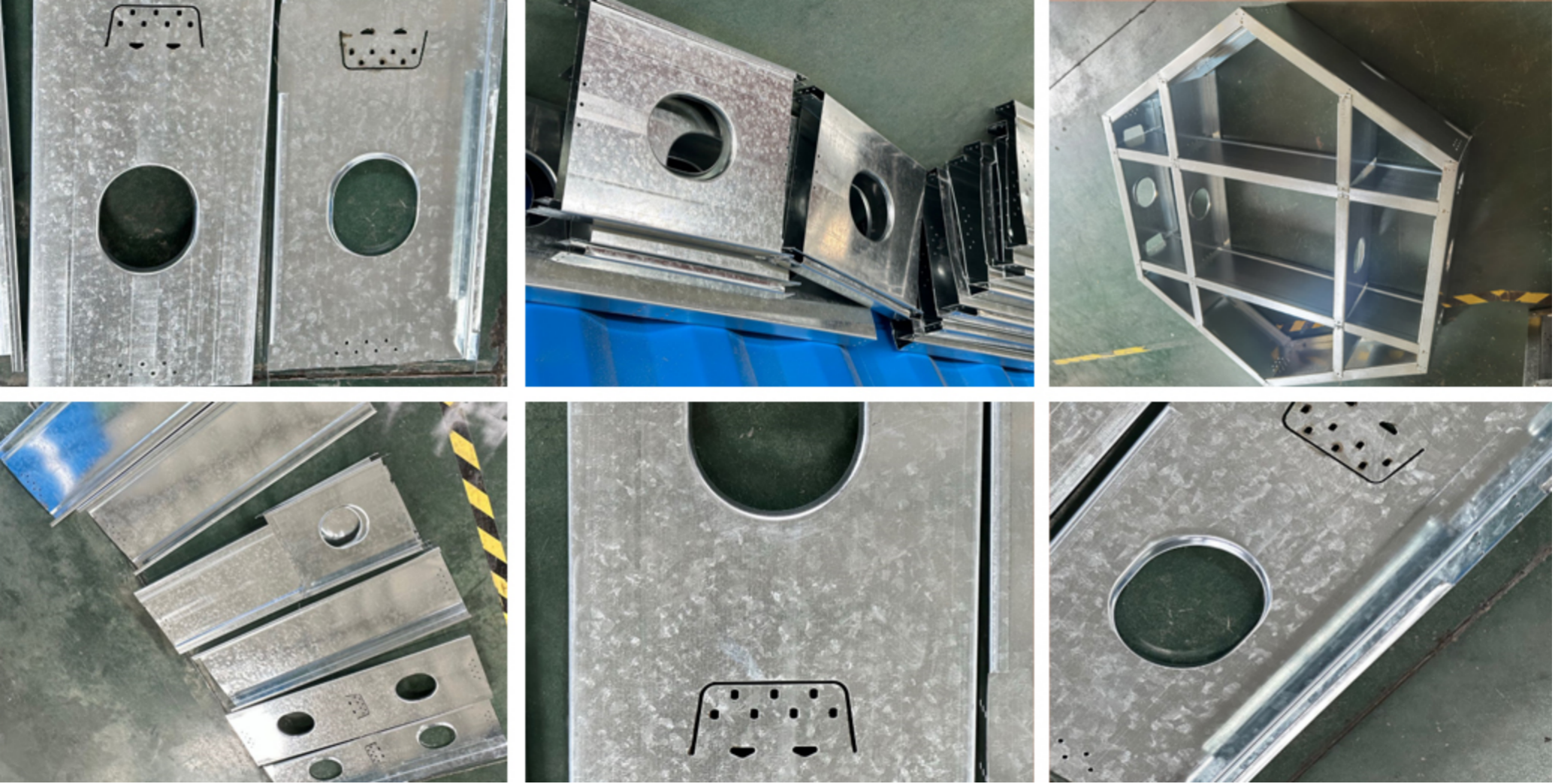

Precision punching after forming ensures perfect alignment By punching notches after the steel is formed, RollMac achieves high dimensional accuracy and precise feature placement. This process allows for seamless connections and reduces the need for rework |

Dual-Web Design Incorporating a twin-web structural configuration,this system produces two distinct web widths from a single coil width.Serving as a superior alternative to traditional C+U channels,streamlines material |

Patented 0mm-gap connection strengthens every joint RollMac’s innovative stud connection design eliminates gaps and uses no screws, enabling direct load transfer between members. This enhances structural integrity compared to traditional friction-based systems |

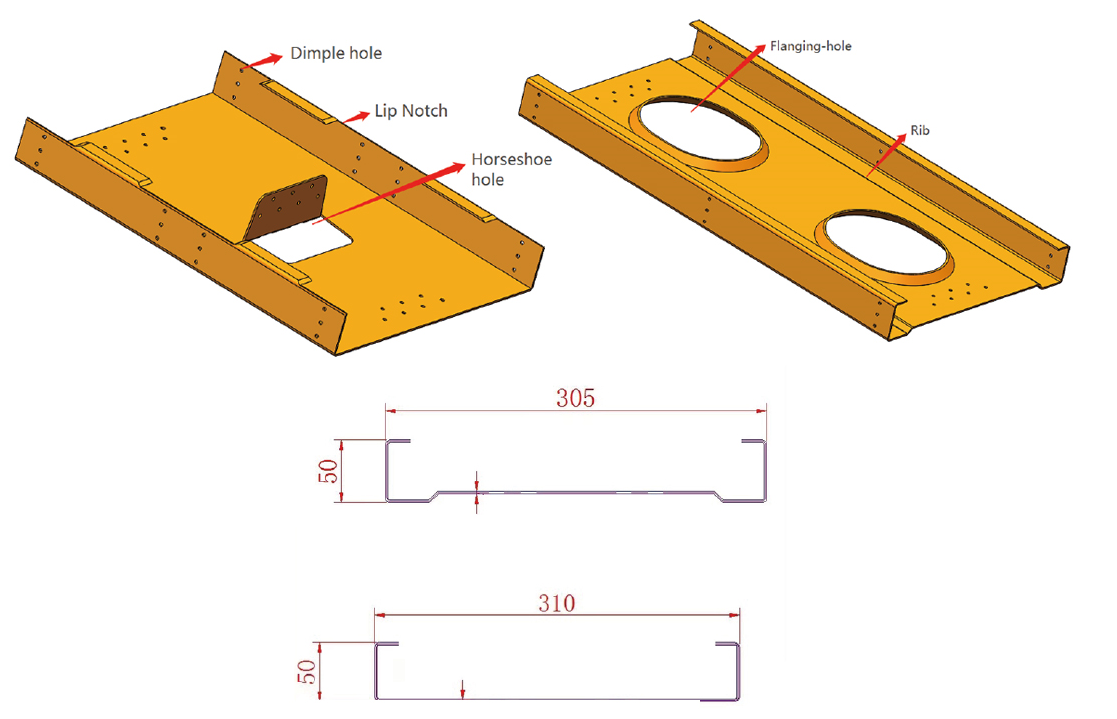

RollMac-C310 steel frame machine Specification | ||||||||

STEEL STRIP Profile Dimensions(±1mm):C310*50*12mm | ||||||||

web | flange | lip | Thickness | Raw Material | ||||

305/310 | 50 | 12 | 1.5-2.5 | G300-G550 GI/GL strip | ||||

HYDRAULIC UNCOILER MACHINE | ||||||||

Strip Width | Coil Exterior Diameter | Rated Load | Main Motor Power | Material Width | ||||

C=425mm | ≤1300mm | 5T | 4kw | 50-500mm | ||||

ROLL FORMER MACHINE-HEAT TREATMENY | ||||||||

Machine Dimension | Machine Weight | Forming Method | Main Motor | Forming Speed(without punching & cutting) | ||||

8000x1200x1200mm | 8T | 12 stations(cold roll forming) | 20kw Servo Motor(Shenzhen Vector) | 20m/min | ||||

HYDRAULIC PUNCHER/CUTTER MOULD-6 sets | ||||||||

Die/Blade Material | Punch & Cutting | Punch/Cutting Tolerance | Cutting Method | Surface Treatment | ||||

Cr12Mov | Post | ±1mm/1mm | Forming Cutter (blanking shear with three blades) | CNC semi-finishing;Vacuum treatment to 58-60HRC CNC refining | ||||

HYDRAULIC STATION | ||||||||

Hydraulic Motor Power | Hydraulic System | Hydraulic Pump/ Reversing Valve Brand | Oil Tank Capacity | Cooler machine | ||||

11kw Hydraulic Motor(Taiwan Brilliance) | Dual Accumulator(production efficiency 30%-40% up) | YUKEN | 260L | Oil Cooler | ||||

Profile Drawing

Delivering quality rollforming systems for the construction industry

In the building and construction sector, the ability to rollform steel with precision is essential. RollMac offers innovative solutions and complete rollforming lines designed specifically for metal framing.

Rollmac Custom Built Machines

RollMac’s Rolling Division provides custom rollforming services through our in-house rolling mills, giving customers the confidence to entrust their production needs to our experienced team.

Our vertically integrated process makes RollMac a true one-stop solution — from initial tooling design and development, to in-house tooling fabrication, and final production launch, we support every step of the journey.

With RollMac’s in-house rollforming experts, customers are assured of receiving high-quality parts, delivered on time and at competitive prices.