RollMac-89-5S

| Availability: | |

|---|---|

| Quantity: | |

The Rollmac C89 steel frame machine is ideal for constructing walls, floors, and roofs for 1–3 level residential buildings,

modular and transportable units, as well as light commercial projects.

0.55-1.2MM

Thickness Range

2700m/hour

Production Speed

4.0m × 0.8m × 1.1m

Dimensions L x W x H

See the Rollmac C89-5S in Action

Post Punching Mould (1) Post-punching cutting structure delivers high precision and rapid operation. (2) Capable of continuous web notch without material jamming. (3) Equipment ensures consistent performance with <0.5% downtime rate. (4) Capable of processing 0.55mm thin-gauge material with consistent performance and zero operational downtime. (5) Dual stiffening ribs on web sections enhance load-bearing capacity by 28%. |

Lower Material Wasting (1) Consistent Operation, Reduced Waste. The post-punching and cutting process guarantees high stability and minimizes failure rates, leading to decreased material loss. (2) Short Die Distance, Minimal Waste RollMac’s System with only 0.02m of start-up scrap and less than 1m of the end scrap.Conventional systems can waste over 7m combined due to sensor delays. (3) Savings from Narrow Strips By utilizing a 170–174mm strip steel (which is 10mm narrower than others), RollMac can save up to 659kg of steel for every 200m² of housing, translating to an annual savings of 141 tons at a production rate of 5000m per day. |

Seamless End Cut Connection Patent (1) Key Features: RollMac’s patented design guarantees that vertical studs are securely positioned against the web of both the top and bottom frames, resulting in a 0mm gap. This direct contact enables the studs to support structural loads independently of screws or fasteners, thereby enhancing strength and stability. (2) Other Supplier’s Conventional Connection (for Comparison): Other systems create gaps between horizontal and vertical stubs, this causes the building’s load-bearing weight to transfer onto the screws connecting the stubs,creating significant safety hazards. |

Rollmac-C89-5S Steel Frame Machine Specification | |||||

STEEL STRIP UNCOILER MACHINE | |||||

Type | Main Motor Power | Rated Load | Material Width | Inner Diameter | Coil Exterior Diameter |

Auto Start-Stop Device, convert Motor Driven | 1.5kw | 1.5T | 50-500mm | 450-530mm | ≤1300mm |

ROLL FORMER MACHINE | |||||

Machine Dimension | Machine Weight | Forming Method | Main Power | Forming Speed | Production Capacity |

4000x800x1100mm | 2.5T | 9 stations | 7.5kw Servo Motor | 2700m/hour | 4-5tons/8h |

HYDRAULIC PUNCHER/CUTTER MOULD-6 SETS | |||||

Die/Blade Material | Punch Level/Horizontal/Cutting Tolerance | Punch & Cutting | Cutting Method | Surface Treatment | |

Cr12Mov | ±0.3mm/±0.5mm/0.75mm | Post | Forming Cutter | CNC semi-finishing;Vacuum treatment to 58-60HRC; CNC refining | |

HYDRAULIC STATION | |||||

Main Power | Hydraulic System | Hydraulic Pump/ Reversing Valve Brand | Oil Tank Capacity | Cooler System | Cooler machine |

7.5kw Hydraulic Motor(Taiwan Brilliance) | Single Accumulator | YUKEN | 180L | Compression Refrigeration | Oil Cooler |

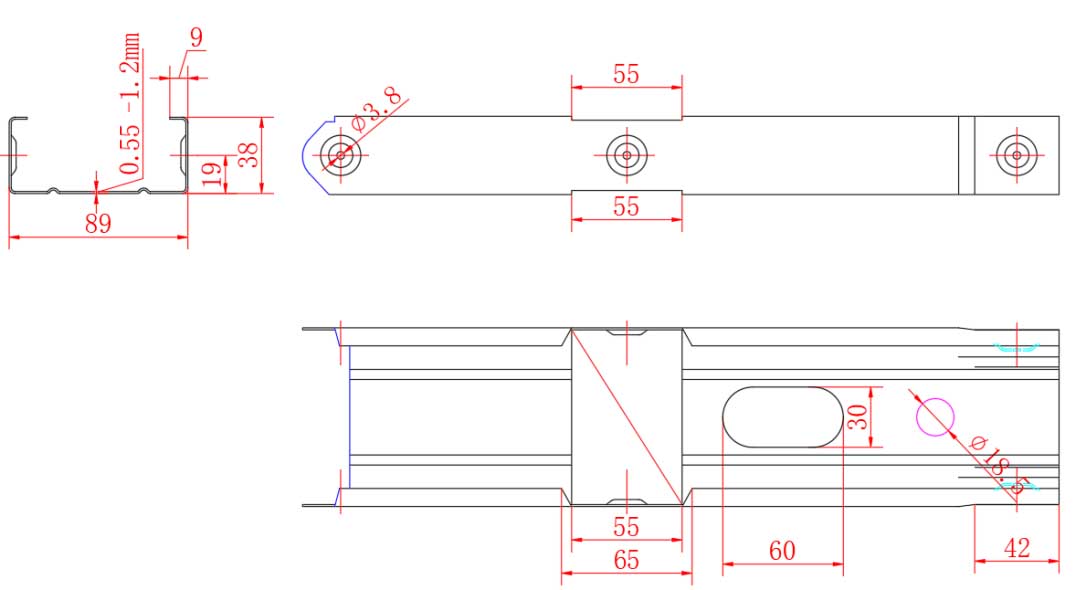

Profile Drawing

Application

Light Gauge Steel framing (LGS) uses cold-formed steel profiles to create strong yet lightweight structural systems. It's widely used in residential homes, mid-rise buildings, and prefabricated modular units. Compared to traditional timber or concrete framing, LGS offers greater precision, better resistance to pests and mold, and a higher strength-to-weight ratio—making it a preferred choice for developers and architects focused on efficiency and sustainability.

LGS framing stands out for its precision manufacturing, durability, and environmental advantages. It reduces material waste, supports fast on-site assembly, and ensures consistent quality—ideal for large-scale modular construction. Steel’s long lifespan and recyclability also make it an eco-friendly option for builders who prioritize sustainability.

Facades & Curtain Walls |

Interior Drywall Framing |

Mid-rise Buildings |

Residential |

Modular Construction |

Commercial Structures |

Rollmac Custom Built Machines

Rollmac has a strong track record in designing and building custom one-off machines and systems, as well as supporting product development. By taking the time to fully understand each customer’s product requirements, we deliver innovative solutions that go beyond simply supplying a light gauge steel framing machine—we help create complete production solutions.

If you require a custom steel frame roll forming machine, please contact the Rollmac head office to discuss your needs and specifications.