| Availability: | |

|---|---|

| Quantity: | |

The C75-305 multi-profile light gauge steel framing machine is designed for the construction of walls, floors, and roofs for residential, modular, and transportable units spanning 1 to 6 levels, as well as for light commercial construction

0.75-2.5MM

Thickness Range

45m/min

Production Speed

75mm to 300mm

Profile Range

See the RollMac C75-305 in Action

Integrated Hydraulic Punching System (1).Enables seamless web punching without extra material flow. (2).Ensures feature placement matches final profile shape. (3).Ideal for cutouts requiring precise alignment with formed contours. (4).Maintains punch accuracy after forming. (5).Clean End-Cut Join. |

Interchangable Dimentional Sets (1) Comprehensive model selection spanning 75mm to 300mm (2) Automated tool-free changeover via single-command operation (3) Clearance-free mechanism with auto-adjusting rollers for varying material gauges. (4) Universal compatibility:Roofing/wall/floor assemblies across small-scale to commercial projects. |

Patented Seamless End-Cut Technology (1).RollMac Patented Fit RollMac’s design locks studs flush to top and bottom frames with zero gap, allowing them to bear loads without relying on screws—boosting strength and stability. (2).Conventional Fit Other systems leave gaps and depend on screw friction, weakening structural performance. |

RollMac-C75-305 steel frame machine Specification | ||||

HYDRAULIC UNCOILER MACHINE | ||||

Strip Width | Coil Exterior Diameter | Rated Load | Main Motor Power | Material Width |

≤500mm | ≤1300mm | 3T | 4kw | 50-500mm |

ROLL FORMER MACHINE-HEAT TREATMENY | ||||

Machine Dimension | Machine Weight | Forming Method | Main Motor | Forming Speed(without punching & cutting) |

8600x1300x1600mm | 10T | 16stations(cold roll forming) | 24kw Servo Motor | 45m/min |

HYDRAULIC PUNCHER/CUTTER MOULD | ||||

Die/Blade Material | Punch & Cutting | Punch/Cutting Tolerance | Cutting Method | Surface Treatment |

Cr12Mov | Pre and Post Punching | ±1mm/1mm | Forming Cutter (blanking shear with three blades) | CNC semi-finishing;Vacuum treatment to 58-60HRC CNC refining |

HYDRAULIC STATION | ||||

Hydraulic Motor Power | Hydraulic System | Hydraulic Pump/ Reversing Valve Brand | Oil Tank Capacity | Cooler machine |

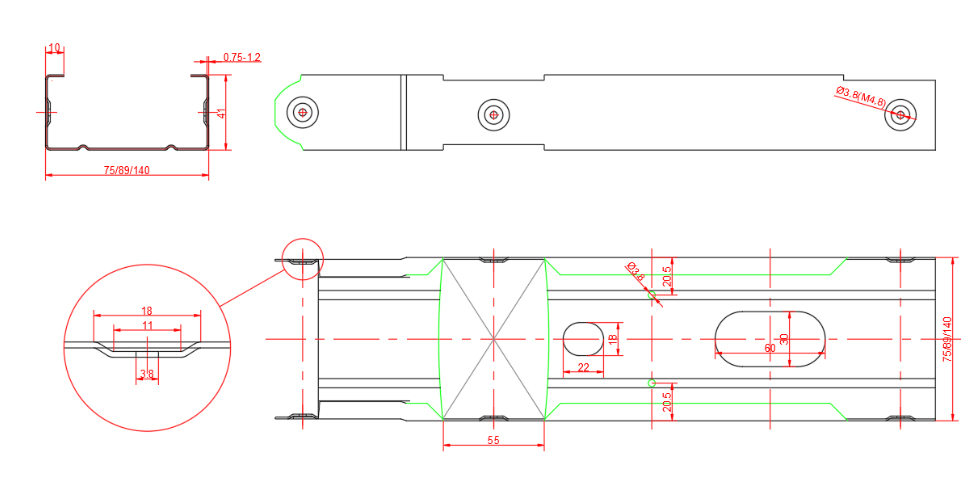

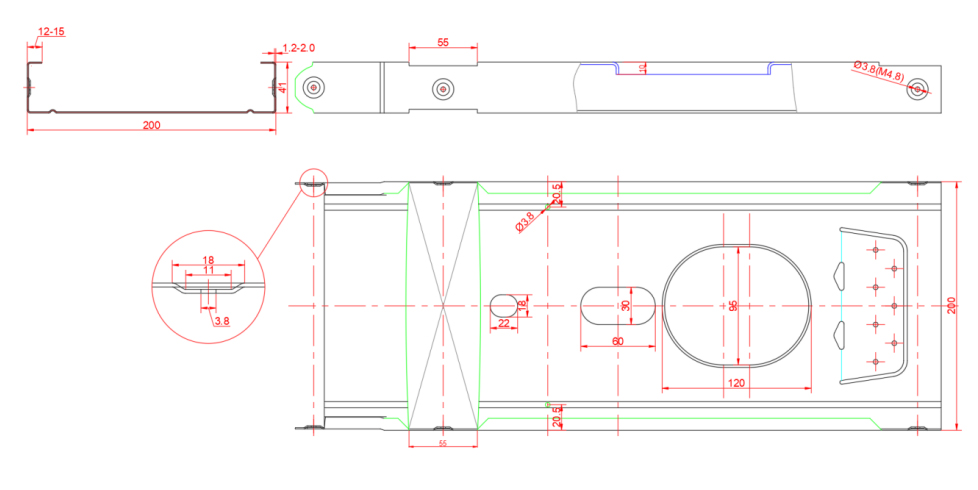

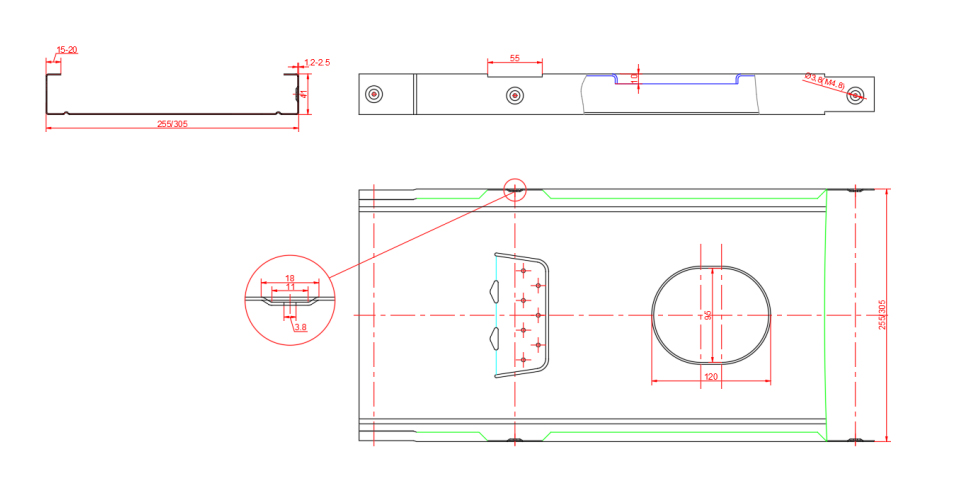

Profile Drawing

Profile 75-140

Thickness:0.75-1.2mm

Profile 200

Thickness:1.2-2.0mm

Profile 255/305

Thickness:0.75-1.2mm

Why Choose RollMac’s Light Gauge Steel Machine:

RollMac is a specialized manufacturer dedicated to producing high-quality roll forming equipment for the construction of light steel frame structures and cold-formed steel structures.

For many years, RollMac has maintained a partnership approach with customers, actively offering effective solutions to guarantee reliable product performance, advanced technology, and ease of operation, thereby elevating users' positions in the competitive market landscape.

All our machines are equipped with a built-in Windows-based control system that accepts basic CSV files from various design software options compatible with our machinery. This feature provides customers with the freedom to choose.

RollMac specializes in the design and manufacture of steel framing machines for panels, trusses, and floor joists in:

- Residential and commercial buildings

- Steel-framed systems for modular and prefabricated structures

- Walls framed for both low and high-rise buildings

- Storage, recreational, and transportable dwellings

RollMac Custom Built Machines

RollMac’s Rolling Division provides custom rollforming services through our in-house rolling mills, giving customers the confidence to entrust their production needs to our experienced team.

Our vertically integrated process makes RollMac a true one-stop solution — from initial tooling design and development, to in-house tooling fabrication, and final production launch, we support every step of the journey.

With RollMac’s in-house rollforming experts, customers are assured of receiving high-quality parts, delivered on time and at competitive prices.