| Availability: | |

|---|---|

| Quantity: | |

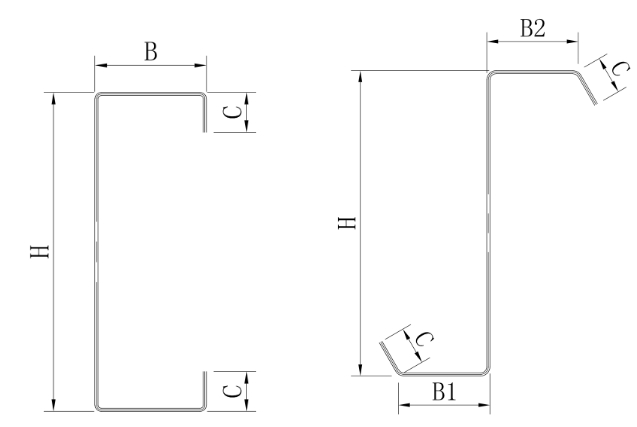

Machines equipped with a variable profile size (within the defined range) and thickness range.Change Size from 100-300 by PLC control in minutes;Change from C to Z by manual rotate the roller.

100-300mm

Effective Width

30m/min

Production Speed

11m × 1.8m × 1.5m

Dimensions L x W x H

See the CZ Purlin Roll Forming Machine in Action

Standard Profile Sizes

Profile Model | C Section(mm) | Thickness(mm) | ||

Web | Flange | Lip | ||

C | 100-300 | 40-100 | 10-20 | 1.2-3.0 |

Z | 120-300 | 40-100 | 10-20 | |

Specifications:

Model | CZ100-300 |

Machine Dimension | 11000*1800*1500mm |

Machine Weight | 11T |

Motor Power | 30kw Servo Power |

Forming Steps | 23steps |

Running Speed | 0-30m/min |

Hydraulic Power | 7.5KW |

Hydraulic Un-coiler | 5 T |

Roller Material | Gcr15&Cr12 |

Cutter Material | Cr12Mov |

Main shaft | 40Cr |

Control System | PLC Control |

High Speed Purlin Roll Forming Machine Main Components

|  |  |

Roll Former 1 set (1)Forming Steps:23 steps; (2)Running Speed:30m/min(without punching and cutting); (3)Main Servo Motor Power:30kw; (4)Roller Material:Gcr15/Cr12,CNC processing and heat treatment,plate (5)hard chrome on the surface; (6)Shaft Material:40Cr with shaft diameter 90mm;Machine Frame:400# H Beam and A3 steel with 30mm thickness | Hydraulic Pre Cutter & Puncher 1 set (1)Cutting method:Flat Cutter,Pre-punching; (2)material of blade & puncher:Cr12Mov; (3)surface treatment:CNC semi-finishing ,Vacuum treatment to 58-60HRC CNC refining | Stepless Adjustable Multi-Funtion Post Cutter (1)Cutting method:Multiple size cutter;Post hydraulic mold cut (2)material of cutter blade:Cr12Mov; (3)surface treatment:CNC semi-finishing ,Vacuum treatment to 58-60HRC CNC refining |

|  | |

Hydraulic System (1)Hydraulic Power:7.5KW; (2)Hydraulic Brand:Yuken; (3)Oil Tank:120L; (4)Cooling System:fan cooling | PLC Controlling System 1 set (Delta Brand) 1)Punching Position Controlling; (2)Cutting Position Controlling; (3)Production Batch Quantity Controlling; (4)Batch Detail Quantity Controlling; (5)Voltage:380V/50HZ/3PH; |

The Benefits of the CZ purlin machine

1. Capable of producing various purlin sizes (C100-300/ Z120-300) without the necessity of changing rollers or spacers.

2. No requirement to change the cutter for different sizes.

3. Simple operation with minimal maintenance costs.

4. Offers infinite sizing (any size within the machine's range), contributing to material savings.

5. Optional punching of holes at any location on the purlin web side and flange side.