| Availability: | |

|---|---|

| Quantity: | |

Fast processing speed Fully automated production using a high-speed turret punching line with a punching speed of 20-50 metres per minute, which is 2-5 times faster than a traditional 9-station punching machine. Using a reasonable cold forming process, forming speeds of up to 50 metres per minute can be achieved. |

Multi-sizes, fast model change The machine includes models C50-160, which can be switched to process any model, and the forming roller mould can be moved in less than 1 minute. Easy forming, no need to adjust the roller gap for changes in material thickness. | No scratches in beautiful appearance Reasonable distribution of cold roll forming angle, to avoid local stress concentration in the forming process to produce indentation, reduce heat generation. The taper forming rollers are lined with bearings to make them passive to avoid scratching the material surface due to speed difference and to reduce heat generation. Adopting no plate thickness adjustment structure, no need to adjust the roller gap for processing different plate thicknesses and avoiding indentation marks on the material caused by the jumping of forming rollers. |

Stable performance, long service life of the main core components reasonably selected Turret punch mould material: SKD11 (Japan mould steel) Roller material: Cr12 Cutter material: SKD11 (Japan mould steel) Main electrical parts: Xinjie, Schneider Main hydraulic parts: YUKEN (Yuken) |

Main technical parameters

1. 4+4T Double-head uncoiler

1)Main power supply: three-phase 380V/50Hz;

2)Control voltage: 24v

3)Automatic start-stop of main spindle;

4)Manually control the contraction of the inner hole of the steel coil;

5)Main motor power 3kw;

6)Discharge width :350mm;

7)Jaws up and down range : 450-530;

8)Rated load: ≤ 4Tx2 rolls.

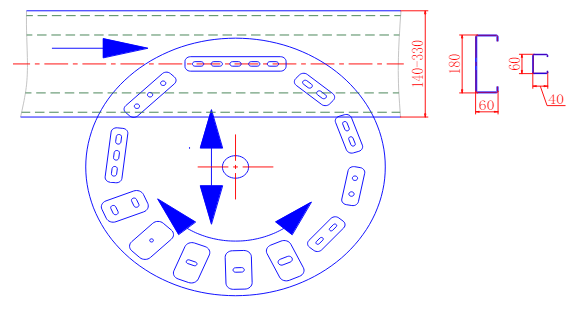

2. ZD/C50-160 Automatic Adjustment Photovoltaic Mounting Machine

(1) . Parameters of raw materials:

Raw material | Strength | Thickness | Material width |

Galvanised/galvanised aluminium-magnesium | ≤550MPa | 1.0-3.0mm | 150mm-320mm |

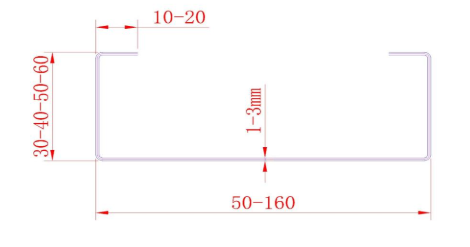

(2) Sectional dimensions:

(3) Main Machine:

1) Main power supply: three-phase 380V/50Hz;

2) Control voltage: 24v;

3) Main motor power: 22kw (frequency conversion motor);

4) Power of change type motor: 0.37kw+0.55kw+1.1kw;

5) cutter motor power: 3kw (servo motor);

6) Hydraulic motor: 7.5kw;

7) Control system brand: Xinjie;

8) Automatic control of processing quantity and cutting length;

9) Length tolerance: ≤±1 mm

10) Rolling speed: 0-50m/min;

11) Forming: feed levelling + 13 passes + shaping;

12) Anti-scratch feeding and oiling device:

13) Material of rollers: Cr12 mould steel, heat-treated to hardness 58-60 after CNC machining;

14) Spindle material: 40cr tempering treatment 280-320HB, after CNC finishing;

15) The frame is made of 400# H-beam + steel plate welding;;

16) Shear mode: stagger after shear, no waste;

17) Cutting knife material: Cr12Mov;

18) blade type: 80x40 first processing, other models to be determined (random with 6 copies, another increase in the cost of the blade for 2000 yuan / pair)

19) Simple 6m finished product pallet 1pc;

20) Machine colour: grey;

3. High-speed turret punching machine

(1) Parameters of raw materials:

Raw material | Strength | Thickness | Material width |

Galvanised/galvanised aluminium-magnesium | ≤550MPa | 1.0-3.0mm | 50mm-400mm |

(2) Machining parameters:

Single/transverse 2-hole | Vertical 2-hole | Vertical 3-hole | Vertical 5-hole |

5 groups | 4 groups | 2 groups | 1 groups |

(3) Distribution of punching mould:

Note: The size of punching mould and grouping of punching mould can be customised according to Party A's requirements.

(4) Main technical parameters:

1) Main power supply: three-phase 380V/50Hz;

2) Control voltage: 24v;

3) Control system: self-developed turret punch control system

4) Automatic control of processing quantity and punching position;

5) Punching position tolerance: ≤ ± 1 mm

6) Clamping host power: 7.5kw (servo motor);

7) Rotary motor: 2kw (servo motor);

8) Turret moving motor: 7.5kw (servo motor)

9) Hydraulic motor power: 11kw;

10) Accumulator model: 16L;

11) Clamping speed: 100m/min;

12) Combined punching speed 20-60m/min;

13) 12 sets of mould turret: 1 set. 14;

14) Hydraulic cylinder: 3 groups;

15) Mould material: Cr12Mov;

16) Production process flow chart.