Rollmac U21-72

| Availability: | |

|---|---|

| Quantity: | |

See the Rollmac U21-72 PV Bracket Machine in Action

Core Advantages of RollMac Solar Mounting Roll Former

Precision

| High Efficiency

| Hassle-Free Operation

|

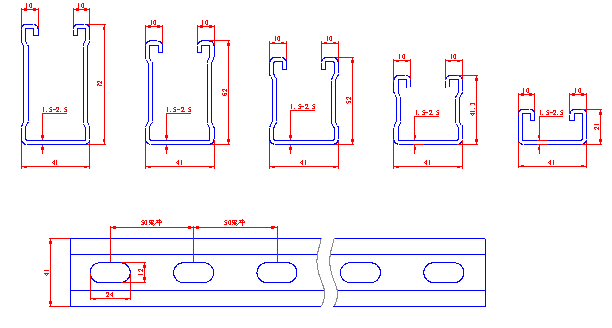

Profile Sizes:

| Rollmac U21-72 PV Mounting Machine Specification | ||

Profile Specification | Machine Main Specification | Technician Support |

★ 41mm U-section Width ★ 21~72mm U-section Flange Height ★ 1.5-2.5mmThickness Range ★ G355(355mpa) Y.S GI/GL material ★ PLC control changing web size in 1 minute ★ Non-stop cutting (fly shearing) system | For Machine ☆ 37kw Motor Driving Power ☆ 4kw Hydraulic Motor Power ☆ 3kw Servo tracking motor for cutting ☆ Precision 24-stations for roll forming ☆ 50m/min running speed ☆ Cr12 Roller Material:Superior material selection and exquisite craftsmanship for the whole machine For Punching ☆ 15kw Motor Driving Power ☆ 50m/min hole rolling speed ☆ Available running web size:98-200mm | √ 12-month product warranty √ Lifelong technical support √ 24/7 global tech consultation via phone or online chat √ Real-time remote troubleshooting & software debugging √ On-site ops & maintenance technical training √ Regular equipment maintenance advice & inspection guidelines √ Comprehensive technical docs package (manuals, videos, guides) |

Product Detail

|  |  |

|  |  |

Application Scenarios

✅ Distributed PV power station bracket production (industrial/commercial workshops, residential rooftops)

✅ Concentrated PV power station U-type bracket processing

✅ Bracket manufacturing for agri-PV and fishery-PV complementary projects

✅ Supporting production for rooftop distributed PV bracket installation

✅ Custom processing of U-type brackets for BIPV (Building-Integrated Photovoltaics) projects

✅ Bracket production for residential small-scale PV systems

✅ Mass manufacturing of brackets for PV poverty alleviation projects

✅ Bracket processing for PV power stations in special environments (deserts, plateaus)